Trave à H in acciaio à bassu tenore di carbone in forma di I DIN IPE IPN Q195 Q235 Q345B Profilu in acciaio à I

UIPEE travi (norma europea) è IPN (norma europea) sò cumunemente aduprate in l'industrie di a custruzzione è di l'ingegneria. Queste travi sò fatte d'acciaiu è anu proprietà specifiche chì li rendenu adatti per supportà carichi strutturali in edifici, ponti è altre applicazioni.

A trave IPN, cunnisciuta ancu cum'è trave I standard, hà una sezione trasversale simile à a trave IPE, ma hè carattarizata da e so flange ligeramente rastremate. Stu cuncepimentu offre una resistenza à a flessione aumentata è hè spessu adupratu in applicazioni induve ci sò esigenze specifiche per a capacità portante è e prestazioni strutturali.

E travi IPE è IPN sò tramindui largamente aduprate in prughjetti di custruzzione è d'ingegneria induve un supportu strutturale robustu è affidabile hè essenziale. E so dimensioni standardizate è e so proprietà meccaniche li rendenu faciuli da travaglià è da integrà in una varietà di disinni è sistemi strutturali.

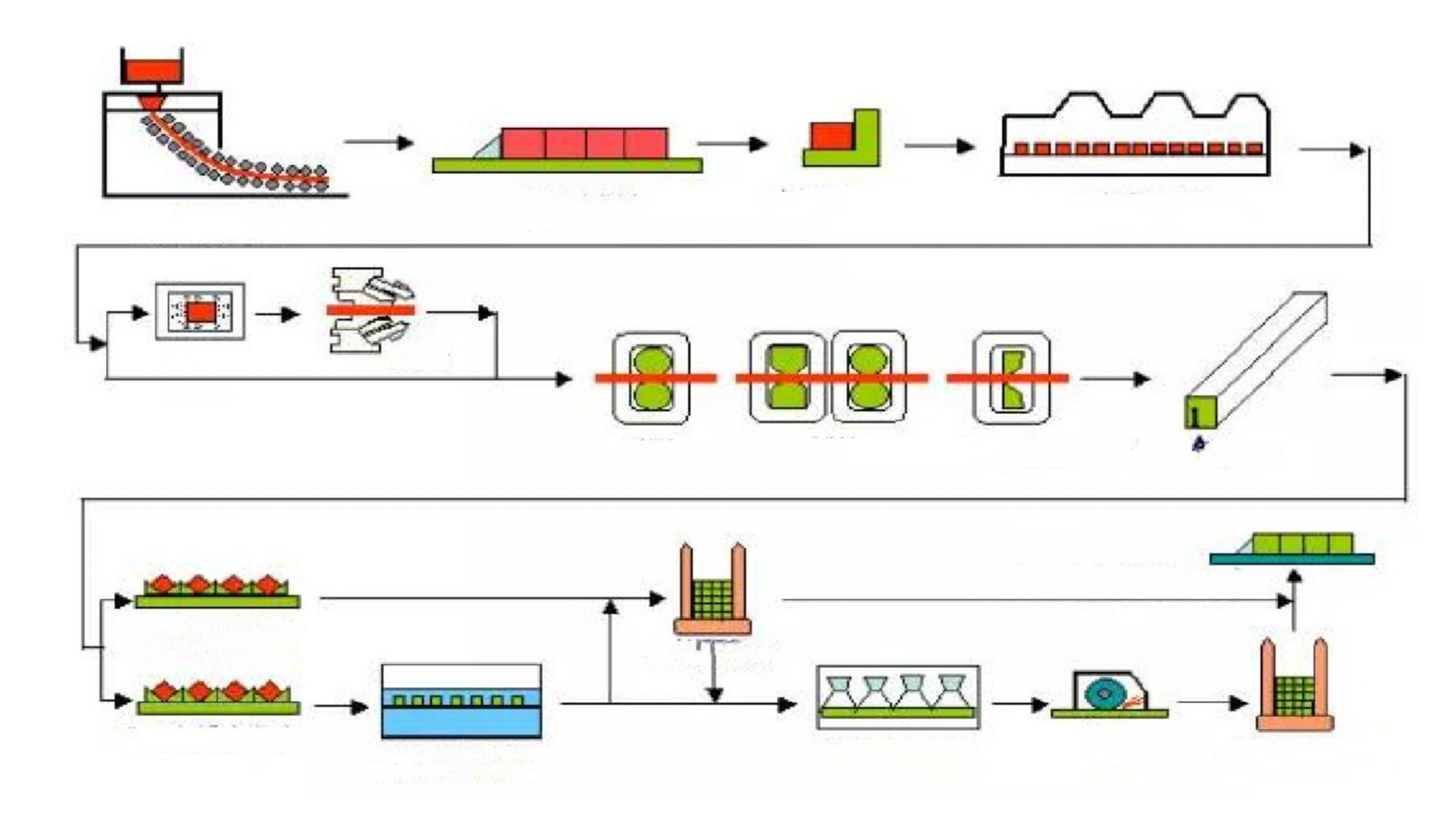

PROCESSU DI PRODUZIONE DI PRODOTTI

UIPEE travi (norma europea) è IPN (norma europea) sò cumunemente aduprate in l'industrie di a custruzzione è di l'ingegneria. Queste travi sò fatte d'acciaiu è anu proprietà specifiche chì li rendenu adatti per supportà carichi strutturali in edifici, ponti è altre applicazioni.

A trave IPN, cunnisciuta ancu cum'è trave I standard, hà una sezione trasversale simile à a trave IPE, ma hè carattarizata da e so flange ligeramente rastremate. Stu cuncepimentu offre una resistenza à a flessione aumentata è hè spessu adupratu in applicazioni induve ci sò esigenze specifiche per a capacità portante è e prestazioni strutturali.

E travi IPE è IPN sò tramindui largamente aduprate in prughjetti di custruzzione è d'ingegneria induve un supportu strutturale robustu è affidabile hè essenziale. E so dimensioni standardizate è e so proprietà meccaniche li rendenu faciuli da travaglià è da integrà in una varietà di disinni è sistemi strutturali.

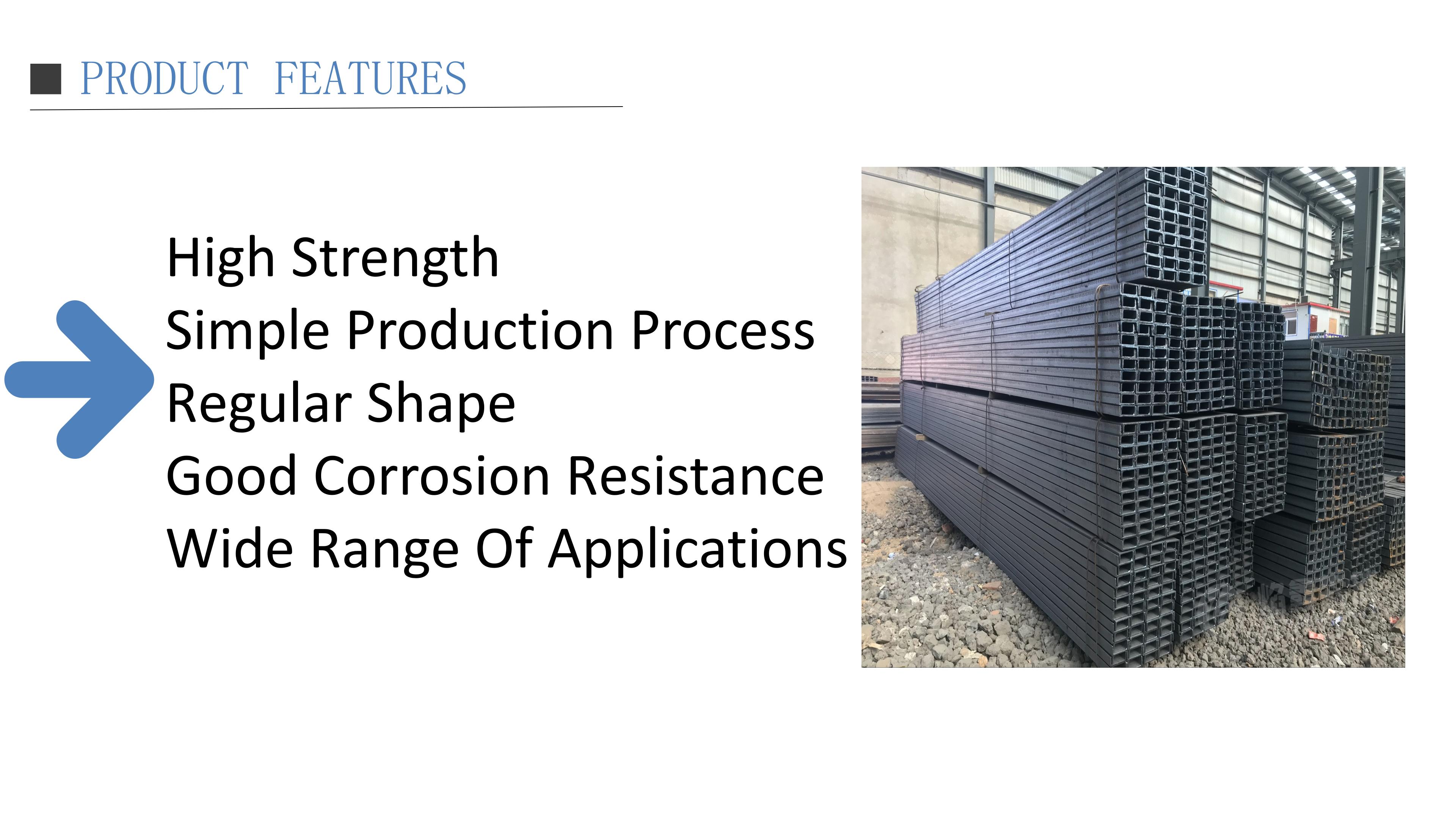

CARATTERISTICHE

A trave IPN, cunnisciuta ancu cum'è trave "IPE", hè un tipu di trave standard europea utilizata in applicazioni di custruzzione è ingegneria. Hà una sezione trasversale caratteristica in forma di I cù flange parallele. A trave IPN hè cuncipita per a resistenza, a rigidità è a capacità portante. Hè cumunemente aduprata in a custruzzione di edifici è strutture, cumpresi ponti, strutture industriali è altre applicazioni induve hè necessariu un supportu forte. E dimensioni è e proprietà standardizate di e travi IPN li rendenu adatti per una vasta gamma di prughjetti di custruzzione.

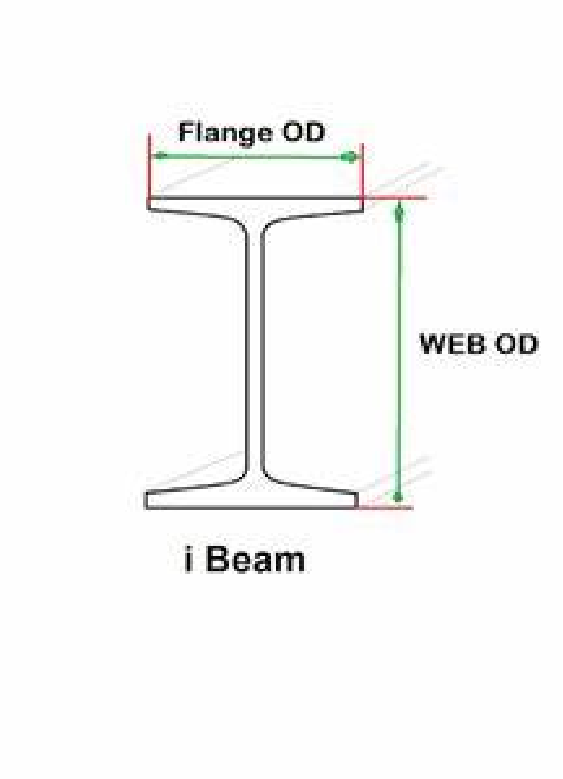

Travi IPN:

Larghezza di flangia larga è spessore di flangia

Adattu per applicazioni strutturali pesanti

Fornisce una bona capacità di carica è resistenza à a flessione

| Designazione | Unità Pesu (kg/m²) | Sezionale Standard Dimensione (mm) | Sedional Zona (cm | |||||

| W | H | B | 1 | 2 | r | A | ||

| IPE300 | A | 36,5 | 297.0 | 150.0 | 6.1 | 9.2 | 15.0 | 46,5 |

| ■ | 42.2 | 300.0 | 150.0 | 7.1 | 10.7 | 15.0 | 53,8 | |

| O | 49.3 | 304.0 | 152.0 | 8.0 | 12.7 | 15.0 | 62,8 | |

| IPE330 | A | 43 | 327 | 160 | 6.5 | 10 | 18 | 54,74 |

| ■ | 49.2 | 330 | 160 | 7.5 | 11.5 | 18 | 62.61 | |

| O | 57 | 334 | 162 | 8.5 | 13.5 | 18 | 72,62 | |

| IPE360 | A | 50.2 | 357.6 | 170.0 | 6.6 | 11.5 | 18.0 | 64.0 |

| ■ | 57.1 | 360.0 | 170.0 | 8.0 | 12.7 | 18.0 | 72,7 | |

| IPE400 | A■ | 57.466.3 | 397.0400.0 | 180.0180.0 | 7.08.6 | 12.013.5 | 21.021.0 | 73.1084.46 |

| 0 | 75,7 | 404.0 | 182.0 | 9.7 | 15.5 | 21.0 | 96.4 | |

| IPE450 | A | 67.2 | 447 | 190 | 7.6 | 13.1 | 21 | 85,55 |

| ■ | 77,6 | 450 | 190 | 9.4 | 14.6 | 21 | 98,82 | |

| 0 | 92.4 | 456 | 192 | 11 | 17.6 | 21 | 117,7 | |

| IPE500 | A | 79.4 | 497.0 | 200.0 | 8.4 | 14.5 | 21.0 | 101.1 |

| ■ | 90.7 | 500.0 | 200.0 | 10.2 | 16.0 | 21.0 | 115,5 | |

| 0 | 107.0 | 506.0 | 202.0 | 12.0 | 19.0 | 21.0 | 136,7 | |

| IPE550 | A | 92.1 | 547 | 210 | 9 | 15.7 | 24 | 117.3 |

| ■ | 106 | 550 | 210 | 11.1 | 17.2 | 24 | 134.4 | |

| O | 123 | 566 | 212 | 12.7 | 20.2 | 24 | 156.1 | |

| IPE600 | A | 108.0 | 597.0 | 220.0 | 9.8 | 17,5 | 24.0 | 137.0 |

| ■ | 122.0 | 600.0 | 220.0 | 12.0 | 19.0 | 24.0 | 156.0 | |

| O | 154.0 | 610.0 | 224.0 | 15.0 | 24.0 | 24.0 | 196,8 | |

| Designazione Cunsultazione | Unità Pesu (kgm) | Dimensioni Abmessungen (mm) | Sezionale Zona mm² x10m² | |||||

| G | H | B | w | f | 1 | 2 | A | |

| IPN 80* | 594 | 80 | 42 | 39 | 59 | 39 | 23 | 757 |

| IPN 100 | 834 | 100 | 50 | 45 | 68 | 45 | 27 | 106 |

| PN 120* | 111 | 120 | 58 | 51 | 77 | 51 | 31 | 142 |

| IPN 140* | 143 | 140 | 66 | 57 | 86 | 57 | 34 | 182 |

| IPN160 | 179 | 160 | 74 | 63 | 95 | 63 | 38 | 228 |

| IPN180 | 219 | 180 | 82 | 69 | 104 | 69 | 41 | 279 |

| IPN 200* | 26.2 | 200 | 90 | 75 | 113 | 75 | 45 | 334 |

| IPN 220* | 311 | 220 | 98 | 81 | 122 | 81 | 49 | 395 |

| IPN 240* | 362 | 240 | 106 | 87 | 131 | 87 | 52 | 461 |

| IPN 260* | 419 | 260 | 113 | 94 | 141 | 94 | 56 | 533 |

| IPN 280 | 479 | 280 | 119 | 101 | 152 | 101 | 61 | 610 |

| PN 300* | 542 | 300 | 125 | 108 | 162 | 108 | 65 | 690 |

| PN 320* | 610 | 320 | 131 | 115 | 173 | 115 | 69 | 777 |

| PN 340* | 680 | 340 | 137 | 122 | 183 | 122 | 73 | 867 |

| IPN 360* | 761 | 360 | 143 | 13 | 195 | 13 | 78 | 970 |

| IPN 380* | 840 | 380 | 149 | 137 | 205 | 137 | 82 | 107 |

| IPN 400 | 924 | 400 | 155 | 144 | 216 | 144 | 86 | 118 |

| IPN 450* | 115 | 450 | 170 | 162 | 243 | 162 | 97 | 147 |

| IPN 500* | 141 | 500 | 185 | 18 | 27 | 18 | 108 | 179 |

| IPN 550* | 166 | 550 | 200 | 19 | 30 | 19 | 119 | 212 |

| IPN 600* | 199 | 600 | 215 | 216 | 324 | 216 | 13 | 254 |

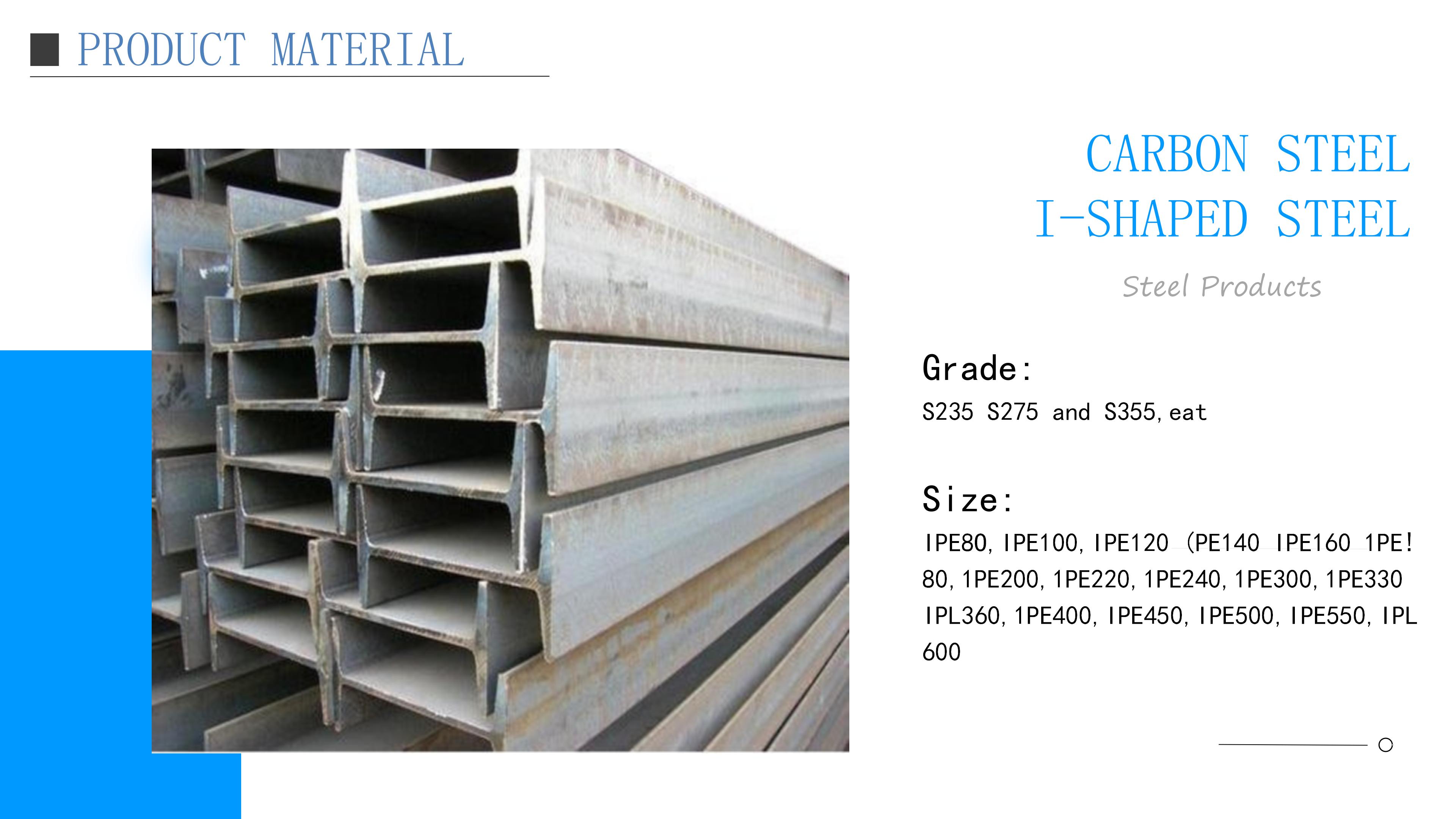

ACCIAIU DIN A FORMA DI I:

Specifiche: IPE8O, IPE100, IPE120 (PE140 IPE160 1PE!

80,1PE200,1PE220,1PE240,1PE300,1PE330

IPL360, 1PE400, IPE450, IPE500, IPE550, IPL600

Norma: EN10034:1997 EN10163-3::2004

Materiale: S235 S275 è S355, manghjate

APPLICAZIONE

A trave IPN, cunnisciuta ancu cum'è una trave I standard europea cù una flangia parallela, hè cumunamente aduprata in a custruzzione è l'ingegneria strutturale. Hè spessu impiegata in varie applicazioni cum'è a custruzzione di edifici è infrastrutture, è ancu in i settori manifatturiero è industriale. U disignu è e caratteristiche strutturali di a trave IPN a rendenu adatta per supportà carichi pesanti è furnisce un supportu strutturale essenziale in una vasta gamma di prughjetti di custruzzione è ingegneria. A so versatilità è a so capacità portante ne facenu una scelta ideale per parechje applicazioni induve a forza è l'integrità strutturale sò essenziali.

IMBALLAGIU È SPEDIZIONE

Imballaggio è prutezzione:

L'imballaggio ghjoca un rolu essenziale in a prutezzione di a qualità diAcciaiu à trave Hdurante u trasportu è u almacenamentu. U materiale deve esse imballatu in modu sicuru, aduprendu cinghie o bande ad alta resistenza per impedisce u muvimentu è i danni potenziali. Inoltre, devenu esse prese misure per prutege l'acciaiu da l'esposizione à l'umidità, a polvere è altri fattori ambientali. Imballà i fasci in materiale resistente à l'intemperie, cum'è plastica o tela impermeabile, aiuta à prutege contr'à a corrosione è a ruggine.

Caricamentu è assicurazione per u trasportu:

U caricamentu è a fissazione di l'acciaiu imballatu nantu à u veiculu di trasportu devenu esse fatti cù cura. L'impiegu di apparecchiature di sollevamentu adatte, cum'è carrelli elevatori o gru, garantisce un prucessu sicuru è efficiente. E travi devenu esse distribuite uniformemente è allineate currettamente per impedisce ogni dannu strutturale durante u trasportu. Una volta caricata, a fissazione di u cargu cù vincoli adeguati, cum'è corde o catene, garantisce a stabilità è impedisce u spostamentu.

I CLIENTI VISITANU

FAQ

1. Cumu possu ottene una quotazione da voi?

Pudete lascià un missaghju, è risponderemu à ogni missaghju in tempu.

2. Cunsegnerete a merce in tempu?

Iè, prumettimu di furnisce prudutti di a megliu qualità è di cunsegna in tempu. L'onestà hè u principiu di a nostra cumpagnia.

3. Possu ottene campioni prima di l'ordine?

Iè, sicuru. Di solitu i nostri campioni sò gratuiti, pudemu pruduce per mezu di i vostri campioni o disegni tecnichi.

4. Chì sò i vostri termini di pagamentu?

U nostru termine di pagamentu abituale hè un accontu di 30%, è u restu contr'à B / L. EXW, FOB, CFR, CIF.

5. Accettate l'ispezione di terze parti?

Iè assolutamente, accettemu.

6.Cumu pudemu fidà ci di a vostra cumpagnia ?

Ci spezializemu in l'affari di l'acciaiu dapoi anni cum'è fornitore d'oru, a sede si trova in a pruvincia di Tianjin, benvenuti à investigà in ogni modu, per tutti i mezi.